Source: Fibre2Fashion

Nylon is a very useful synthetic material. It is a polymer with very long, heavy molecules made up of small endlessly repeating segments of atoms that can be moulded into any product or drawn into fibres for making fabrics. Discovered in 1930, nylon is not one single substance, but a name given to a whole family of very similar materials called polyamides.

Nylon is a silky, smooth plastic which is strong and durable. It is waterproof and fast-drying as water molecules cannot easily penetrate the surface. Although nylon is used in many everyday products, it dissolves in phenol, acids and any other harsh chemical. Nylon is highly resistant to attack from natural harmful moulds, insects and fungi.

Nylon, in itself, does not exist in nature. It is made in chemical plants from organic chemicals found in natural resources such as coal or petroleum. Nylon fabrics are not made from chips, but from fibres of nylon. They are made by melting nylon chips and drawing them through a spinneret, which is a wheel or plate with many tiny holes in it. Fibres of different length and thickness are made by using holes of different size and drawing them out at different speeds.

The first products made from nylon were toothbrushes and women's stockings. Later, it has been used practically in everything from tennis rackets and parachutes to low-cost machine gears, fishing nets and nylon rugs. Some cars even have body parts made from nylon. In India, nylon is mostly used in textiles, tyre cords and engineering plastics. The primary type used is nylon-6. Globally, textiles are the largest application for nylons, but in India it is the industrial segment that is the largest.

Production:

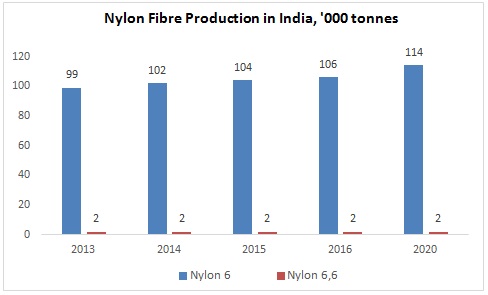

In India, mainly nylon 6 is produced as compared to nylon 6,6. As shown in the graph, it is estimated that production growth will continue and will reach 114,000 tonnes of nylon 6 fibre while nylon 6,6 will remain steady at around 2,000 tonnes till 2020.

China is the largest consumer and manufacturer of nylon fibres. Its growing population has enhanced the growth of the textiles industry which in turn is expected to boost the overall growth of the nylon market. Rest of Asia is expected to be an emerging market for nylon fibres. The growing textiles industry in Japan, Taiwan and India are expected to boost the overall nylon fibre market. Owing to the presence of a large automobile industry, Europe will show quick growth in the overall demand of nylon fibres.

Raw material capacities and production:

The total export value of NFY was about 1.15 million kg in 2015 and its major export markets are Japan, Hong Kong, Korea, Thailand and the US. The total import value of NFY was about 1.35 million kg in 2015 and the major import markets are Russia, the US, Germany, China and Thailand.

In 2014, India accounted for a volume share of 2.25 per cent in global nylon production. In India, the demand for nylon stood at 67.75 thousand metric tonnes in 2015 and it is expected to grow at a CAGR of 5 per cent over the next five years. Nylon 6 will see the highest growth of 5.2 per cent by 2020. The global demand for nylon 6,6 is estimated to exceed a market worth US$870 million by 2020. The overall polyamide global market is expected to stand at US$31 billion in 2020.